In the history of Motorcycling many brands of motorcycles have blazed a glorious trail and made themselves famous by their feats of speed endurance, dependability or style. Although many of these makes are no longer with us, they have not past into oblivion, but are still well remembered and cherished by the clan of golden antique motorcycle enthusiast.

As many of us are aware, there are an even greater number of names which are seldom heard of and many of which are all but forgotten, even though many of these various machines laid the foundation for which the well-known names built their reputations. Among those were the Michaelson and its sister bike, the Minneapolis, which was first introduced to the market place in June of 1908.

The Michaelson motorcycle was conceived and realized in about 1912 by four brothers in the great Twin Cites area of Minnesota, a Metropolis and the home of the Wagner, Thiem, and the Cyclone motorcycles. The Michaelson brothers Jack, Walter, Joe and Anton developed a motorcycle whose design was one of the freshest and advanced concepts to be introduced into the motorcycle world.

The Michaelson Motor Company’s manufacturing plant was in a brick building at 526-530 Fifth Street South in Minneapolis. Jack was the president and treasurer, Walter was the vice president, the superintendent and the machinist, A.E. Peterson was secretary and Mr. Shapiro was an investor.

Joe Michaelson had a considerable amount of mechanical experience; he served as the draftsman and was instrumental in the advanced designs of both the Michaelson and the Minneapolis motorcycle, both of which were manufactured at the Fifth Street plant.

Earlier, Joe had designed and built a two cylinder, air-cooled auto entirely by himself. That was quite a feat around 1910.

The Michaelson and the Minneapolis were quite similar in mechanical aspects and it must be assumed that the greater number of machines manufactured under the Minneapolis brand name was strictly for public relation reasons. Both models were available in single and v-twin cylinder form. The Minneapolis used Thiem and Thor engines that where modified to their specifications.

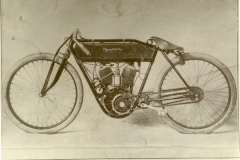

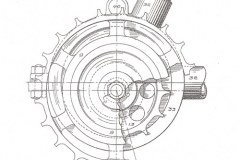

Joe Michaelson also designed a single and twin engine for the Minneapolis motorcycle. The Michaelson engines where built entirely at the Michaelson manufacturing plant by expert workmen with years of experience under the personal direction of Joe Michaelson. The motor is virtually a giant, the bore is three and one and a half inch and the stroke three and three quarter inch. Every motor was tested so it would produce maximum power and speed before it was sent out. The cylinder and the head were one piece. The wide thin fins gave the cylinder plenty of radiation. Mechanical overhead intake and exhaust valves were one and seven eights diameter with adjustable pushrods. The rocker arms on the intake and exhaust are enclosed with caps, which kept out dust and grit. The rockers each had a large oil chamber packed with an oil-saturated wick; the cylinders were carefully nickel plated and polished, as well as other exposed parts. The all aluminum engine case was highly polished for appearance. The whole design for that period was extremely nice and cleaver. The quality of the machines was of the highest degree. Their mechanical details featured an Schebler carburetor, Bosch magneto, chain drive, multiple discs clutches in oil. Overhead valves were on both the single and the twin. The motorcycle also featured leaf front fork suspension.

Lubrication was by mechanical means. A hand pump was provided. The motorcycles were usually fitted with 28″ by 3″ clincher tires. Several Michaelson Tri Cars were made; the Michaelson was the first motorcycle to feature an integral engine transmission, the Michaelson was truly advanced for its time. The Twin Model A Michaelson cost $325.00 and the single Model B Michaelson cost $275.00. The production of these fine motorcycles continued until the late 1914 when the company ran into financial trouble.

Lee W. Oldfield, well-known racing driver from Indianapolis, Indiana, came to Minneapolis to take charge of the Michaelson Motorcycle Company. The company was reorganized with Mr. Oldfield as president and manager. The new secretary and treasurer was I.A. Webb, a well-known mining promoter and capitalist from Deadwood, SD. He invested $50,000 into the company. Their plans were to increase the production of the twin-engine motorcycles and delivery cars and to suspend the single engine motorcycle. Their plans were also to build a larger manufacturing facility in the suburbs of Minneapolis.

Walter Michaelson, then head of the company, resigned. He went on to manufacture the Michaelson Cycle Car, which was just recently placed on the market. The company again ran into financial problems and the stock, assets and parts supply of the company were bought out by the H. E. Wilcox Motor Car Company of Minneapolis, later known for the Wilcox Trucks. This company disappeared from the scene in 1928 and apparently never made plans to revive the wonderful Michaelson Motorcycle.

Walter who was a pioneer designer of the Tri Car went on to manufacture the new Michaelson Tri-car Motorcycle; it was a radical departure from the previous models.

The frame was constructed from pressed steel channels, securely bolted and riveted together. The axel, yokes and spindles were made to carry 500 lbs. or more down bumpy roads. The heavy-duty steel box measured 26″wide x 40″ long and 25″ high. It had double doors in the front and had a hinged top with a 300lb. capacity.

The new Michaelson Tri-car used an internally expanding 8″ inch drum brake. This was the largest brake used on any American Motorcycle at that time. The brake is operated by backpedaling or by a foot pedal attached to a footboard bracket. The advantages of the Michaelson Tri-car over a truck or car was the over all cost of the vehicles, easy to maintain, weighed less than a car or truck so it was easier on the tires and consumed less gas and oil per mile. The brochure stated, ‘Your one horse and delivery wagon costs you more than five cents per mile, your Tri-car costs you less than three cents per mile, including gas tire wear, general up keep and depreciation. Plus a young boy can easily operate a Tri-Car at a comparatively small cost for wages. The same boy that drives a horse twelve miles a day will be able to drive his Tri-car fifty miles a day. This also extends the area you can do business in so you can increase the profitably of your business.’

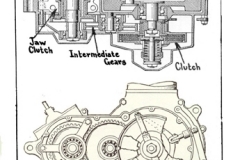

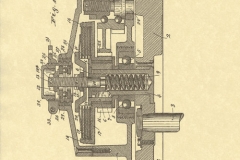

The Tri-Car had a foot starter. The pedal chain is connected directly to the transmission shaft in the motor through a sprocket and silent automatic ratchet to permit the motor to be started with the rear wheel on the ground. The operator of a Michaelson Tri-car need not place his rear wheel on the stand to start the engine. This is an important feature as the driver can make quick starts on delivery calls, and need not keep the motor in operation and thus cut down the gasoline consumption.

The Michaelson Tri-car used a two speed enclosed transmission using a multiple enclosed disc clutch. The gear ratio on the single cylinder was 5 to 1 in high and 10 to 1 in low. The twin cylinder model had a 4 to 1 in high and an 8 to 1 in low. With two speeds on a machine the low gear is always used to start, even on the level. The motor then has sufficient leverage on the rear wheel to make an easy and positive start, even up steep grades without speeding up the motor to excess and with little slipping of the clutch.

This argument is not necessary to any rider who has tried out a Two Speed Machine. Once a two speed rider, always a two speed rider. They all say that the two-speed transmission is worth 5 times what it costs. The Michaelson single called the Roadster had 5 to 6 H.P and cost $395.00. The twin model had 10 to 13 H.P. and cost $425.00 and were painted in lustrous dark red enamel.

Joe, John, Walter and Anton Michaelson have all past away but the memories of the Michaelson and the Minneapolis motorcycles live on.

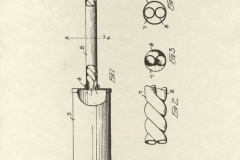

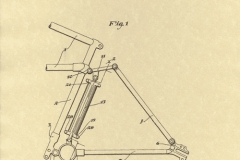

PATENTS